VENSYS WIND TURBINE TECHNOLOGY

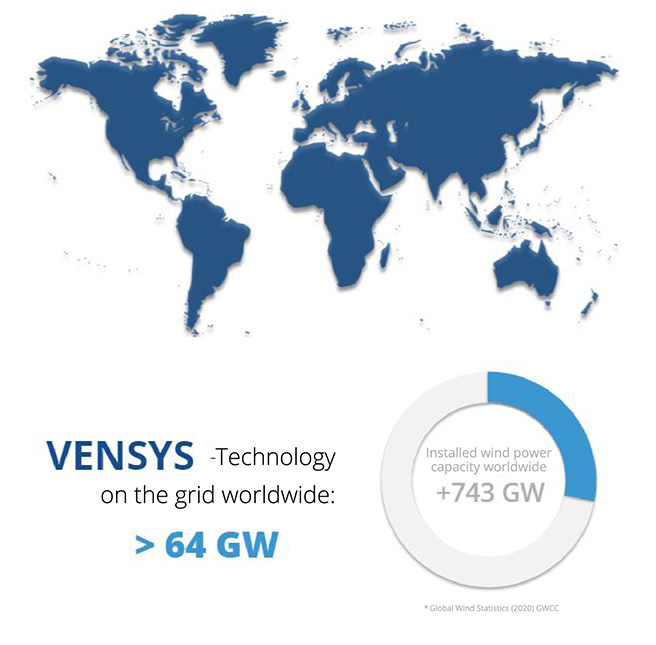

We - VENSYS Elektrotechnik GmbH - have been living our passion for wind energy for many years. Site-specific configuration, continuous development of our technology as well as excellent service are the factors for our success. Our customers’ needs are always our focal point.

With our proven high-performance technology ‘Made in Germany’ we rely on

- maximum performance and availability,

- total cost and profitability of ownership over the entire service life as well as

- optimum service and maintenance contracts.

We create flexible solutions combined with planning security for our customers.

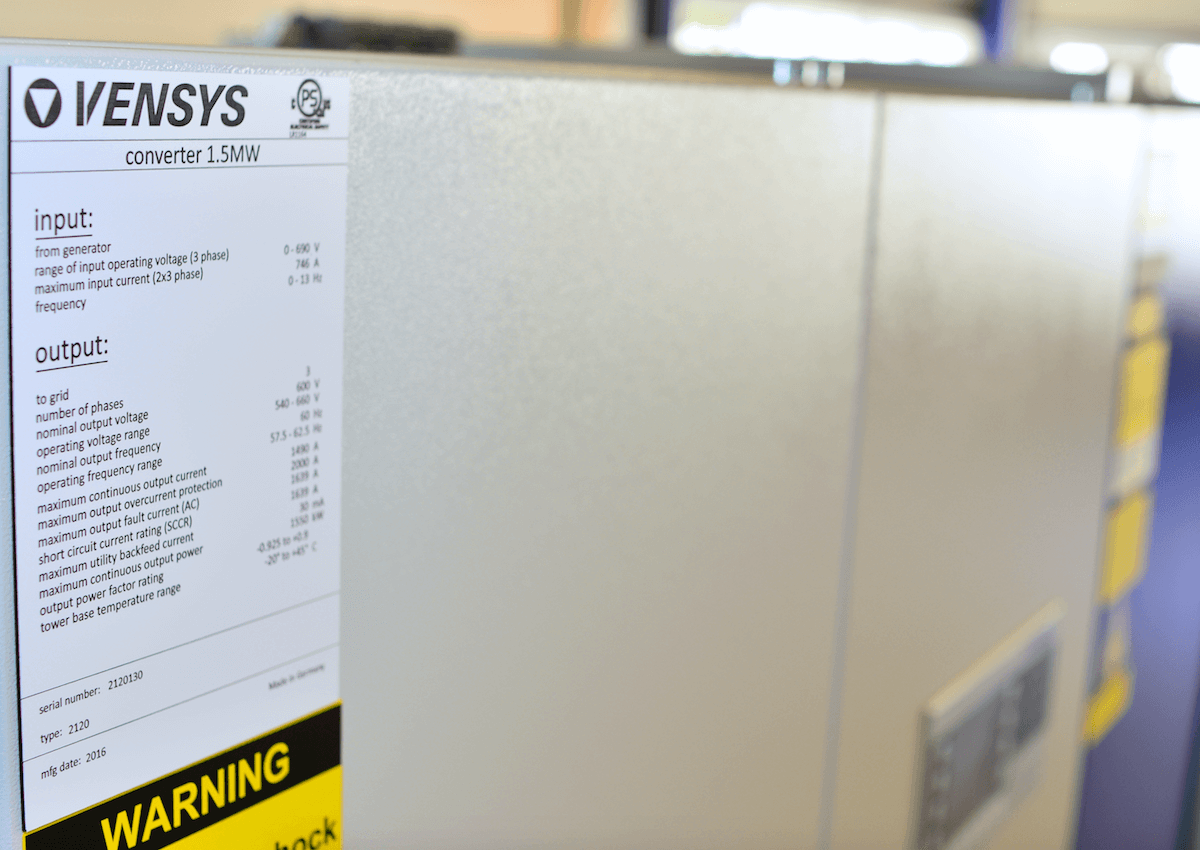

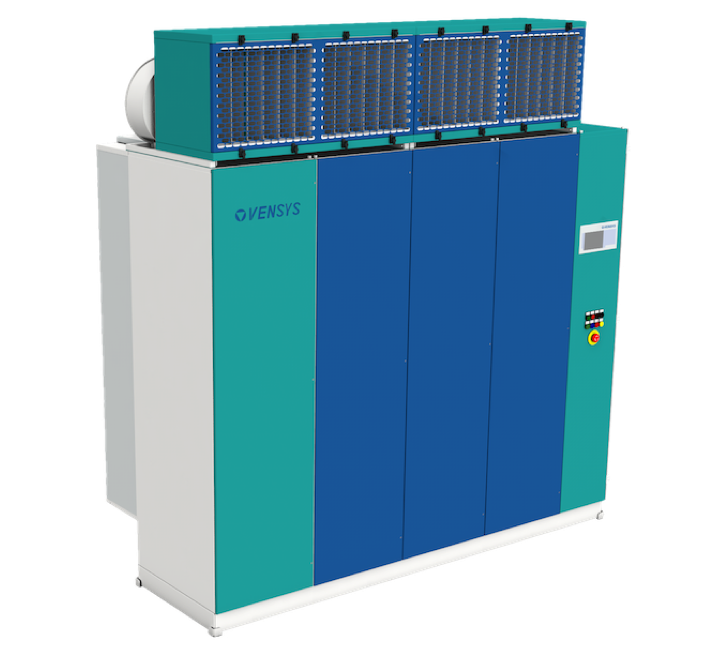

VENSYS CONVERTERS - THE CORE OF EVERY WIND TURBINE

Converters are at the core of a wind turbine - they convert the power gained in the generator in such a way that it can flow into the grid at a constant voltage and constant frequency.

VENSYS converters offer a great power range, from 1.5 MW up to 6 MW, and ensure superior grid compatibility. With their earthed intermediate circuits, our converters operate reliably even at low wind levels and can compensate for short network outages through their LVRT electronics and uphold the consistent operation of the wind turbines.

The modular, easy-to-exchange plug-in units are available with either air or water cooling, making VENSYS converters suitable for global use - even under harsh climatic conditions. VENSYS converters are capable of grid cleaning even while in idle mode - making them both unique and even more attractive from an economic perspective.

VENSYS converter systems have power plant properties and meet the requirements and regulations of various network operators worldwide. All components meet the high quality standards of products engineered and ‘Made in Germany’, thereby guaranteeing high availability of more than 99% and a long life cycle of the wind turbine.

VENSYS CONVERTERS - HIGHLIGHTS: POWERFUL

- Extensive experience in high power converters (from 1.5 MW to 6 MW)

- Modular construction: service friendly, quick repairs

- Grid code compliant

- Water or air cooled: suitable for demanding environments

- Support and spare parts available through licensed partners worldwide

- Comprehensive global service

- Quality ‘Made in Germany’

VENSYS converters comparison:

VENSYS 1500

VENSYS 2500

VENSYS 3000

Open Overview

| VENSYS 1500 | VENSYS 2500 | VENSYS 3000 | |

|---|---|---|---|

| Rated power | 1500 kW | 2500 kW | 3000 kW |

| Type designation | VE 1500 | VE 2500 | VE 3000 |

| Converter control | VE1500H SDL | VE2500 | VE3000 |

| Rated output power | 1500 kVA | 2500 kVA | 3000 kVA |

| Maximum rated output power | 1667 kVA | 2778 kVA | 3333 kVA |

| Maximum continuous current | 1552 A | 2587 A | 3104 A |

| Voltage level | 620V | 620V | 620V |

| Number of phases | 3 | 3 | 3 |

| Cooling type | Air or water cooling | Water cooling | Water cooling |

| Ambient temperature range | -20°C bis +50°C | -20°C bis +50°C | -20°C bis +50°C |

| Input frequency | 4-50 Hz | 4-50 Hz | 4-50 Hz |

| Output frequency | 45-64 Hz | 45-64 Hz | 45-64 Hz |

VENSYS 1500

Open Overview

| VENSYS 1500 | |

|---|---|

| Rated power | 1500 kW |

| Type designation | VE 1500 |

| Converter control | VE1500H SDL |

| Rated output power | 1500 kVA |

| Maximum rated output power | 1667 kVA |

| Maximum continuous current | 1552 A |

| Voltage level | 620V |

| Number of phases | 3 |

| Cooling type | Air or water cooling |

| Ambient temperature range | -20°C bis +50°C |

| Input frequency | 4-50 Hz |

| Output frequency | 45-64 Hz |

VENSYS 2500

Open Overview

| VENSYS 2500 | |

|---|---|

| Rated power | 2500 kW |

| Type designation | VE 2500 |

| Converter control | VE2500 |

| Rated output power | 2500 kVA |

| Maximum rated output power | 2778 kVA |

| Maximum continuous current | 2587 A |

| Voltage level | 620V |

| Number of phases | 3 |

| Cooling type | Water cooling |

| Ambient temperature range | -20°C bis +50°C |

| Input frequency | 4-50 Hz |

| Output frequency | 45-64 Hz |

VENSYS 3000

Open Overview

| VENSYS 3000 | |

|---|---|

| Rated power | 3000 kW |

| Type designation | VE 3000 |

| Converter control | VE3000 |

| Rated output power | 3000 kVA |

| Maximum rated output power | 3333 kVA |

| Maximum continuous current | 3104 A |

| Voltage level | 620V |

| Number of phases | 3 |

| Cooling type | Water cooling |

| Ambient temperature range | -20°C bis +50°C |

| Input frequency | 4-50 Hz |

| Output frequency | 45-64 Hz |

IMPRESSIONS

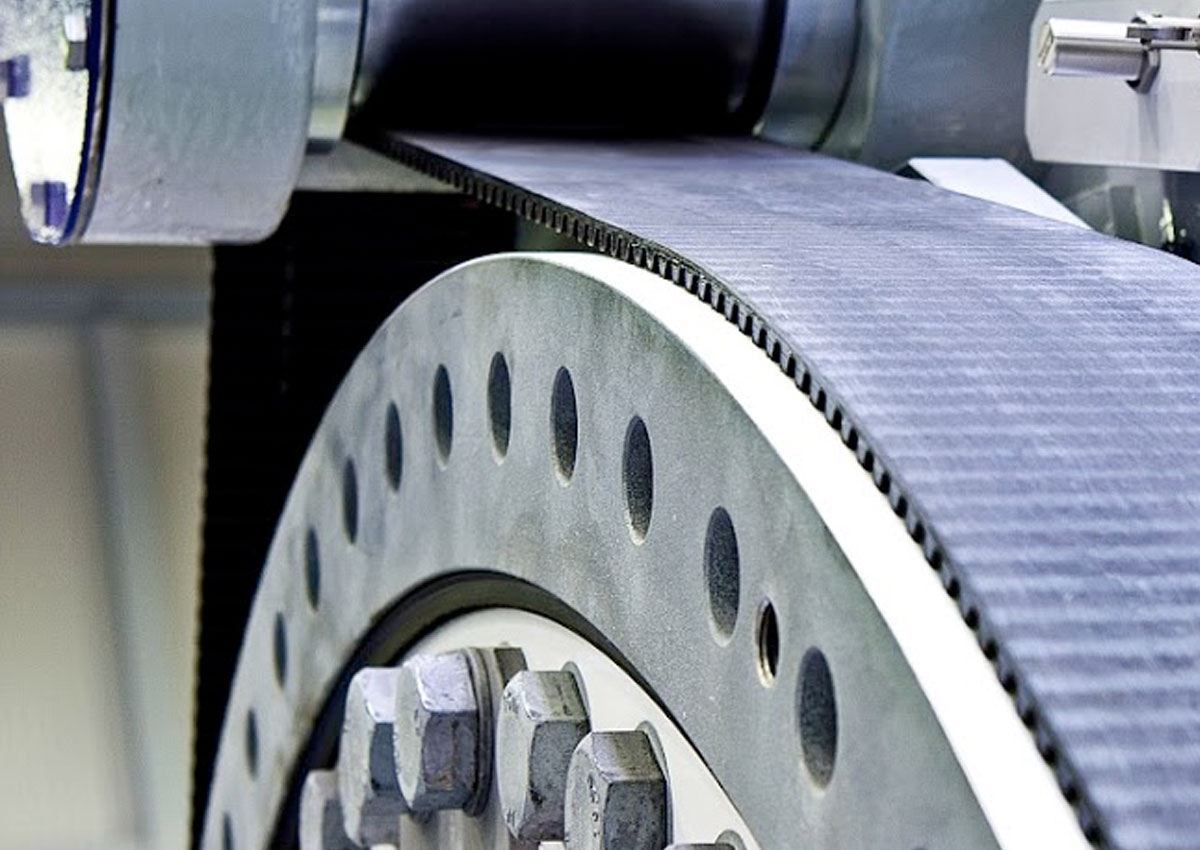

VENSYS PITCH SYSTEM

The position of the rotor blades in the wind determines the rotation speed and therefore the energy yields of the turbine. The finely-tuned adjustment of the blade angle of the VENSYS Pitch System allows for maximum yields. Our pitch system also adjusts the blade angle to the wind pressure or, in case of too strong winds, turns the blades out of the wind completely, thus safeguarding your wind turbine. VENSYS Pitch System is known for its high degree of reliability and safety. Even in case of a grid failure, the capacitors, which are vastly superior to commonly used batteries ensure a safe control of the system. Currently more than 3,000 of our pitch systems are in operation globally and the high-quality components ‘Made in Germany’ ensure long service-free operating cycles.

VENSYS PITCH SYSTEM - HIGHLIGHTS: POWERFUL

- Built by highly qualified technicians at VENSYS factory Germany

- Complete testing of performance and functionality by VENSYS engineering team

- Use of capacitors instead of the usual accumulator batteries

- Proven and tested more than 10,000 times

- Worldwide service

CERTIFIED EMV:

IMPRESSIONS

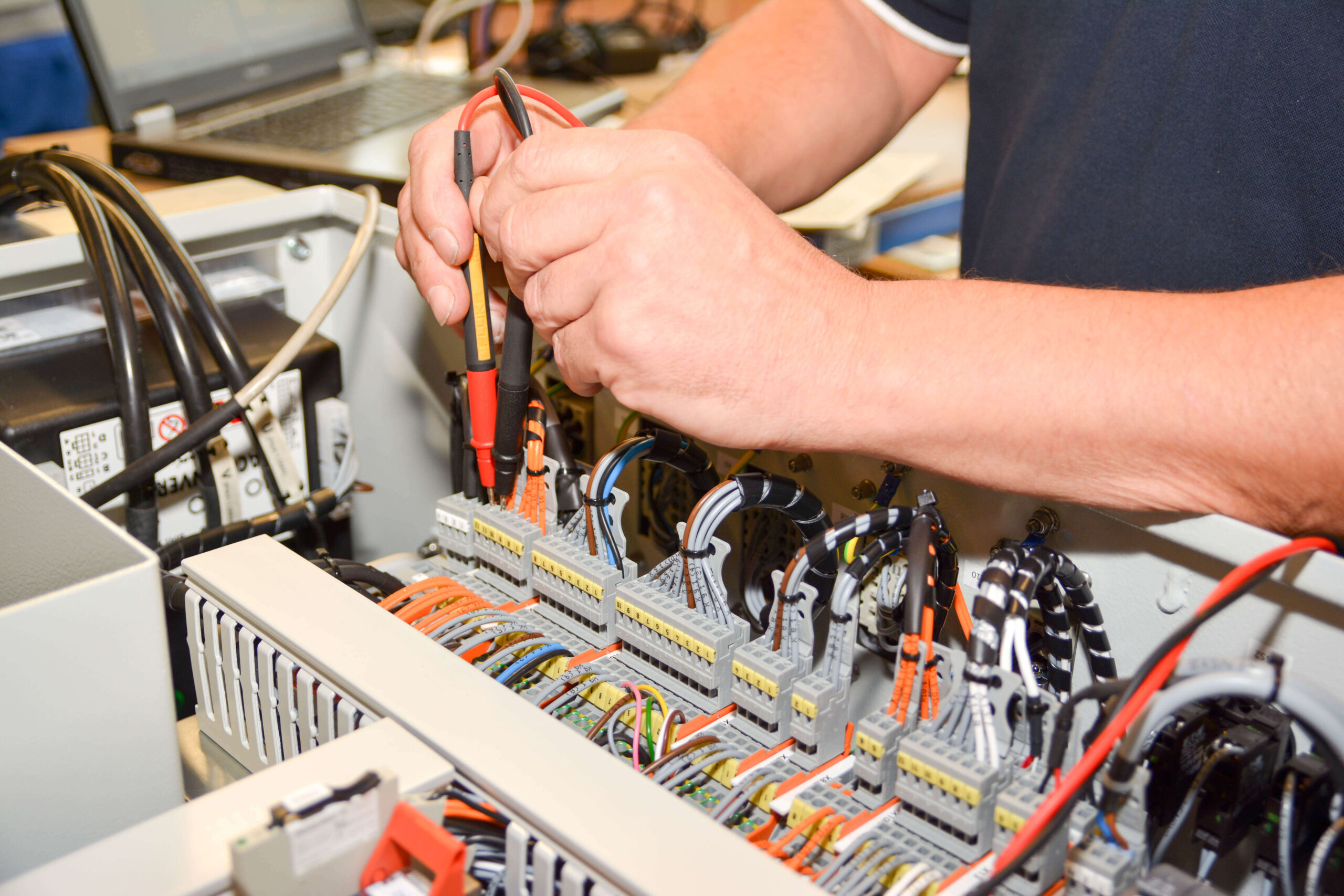

SERVICE PROVISIONS FOR YOUR WIND TURBINES

VENSYS Elektrotechnik is your reliable partner for all service provisions during the entire service life of your wind turbines. In addition to technological innovation and highest quality, our comprehensive service represents the third pillar of VENSYS Elektrotechnik GmbH.

Our highly qualified engineers and technicians support costumers during the planning stage, ensure the smooth construction of the wind turbine as well as high efficiency and profitability of the system for its complete life cycle.

VENSYS Service ensures low operating costs through quick and reliable repair services and smooth-running maintenance management.

Our service technicians are available around the world and can be accessed through the VENSYS-hotline. Our services are based on maintenance solutions that cater to your individual requirements with respect to your location and your specific needs as a wind farm operator.

VENSYS CONVERTERS - HIGHLIGHTS: POWERFUL

- comprehensive monitoring and evaluation

- Available around the world

- Highly qualified engineers and technicians

- Efficient maintenance management (diagnostics and upgrades)

- Maintenance and Service On-Site for converter (wind/solar), mean-voltage transformers as well as control gears

- Spare parts available from licensees around the world

WHAT MAKES VENSYS SERVICE SO SPECIAL:

A unique service and support structure sets us apart from our market competitors;

through close cooperation we create clarity about complex issues.

LONG TERM SERVICE AGREEMENT (LTSA):

The LTSA is our customer-friendly “all inclusive” package. With our LTSA, operators can calculate all operating costs of their WEC – conveniently and hassle-free. The technical availability guarantee provides operators with optimal planning security for their projects.

MAINTENANCE SERVICE AGREEMENT (MSA):

The Maintenance Service Agreement MSA is geared to the individual needs or wind farm operators. With our MSA, operators can use their own service structures, provided that they comply with VENSYS requirements. In doing so, operators can rely on the support of VENSYS technicians any time.