VENSYS SOLAR TECHNOLOGY

VENSYS Elektrotechnik GmbH played a pioneering role in 2010, when the first Inverters was developed for a solar park. Extensive experience from the field of wind energy contributed in the creation of an innovative and sustainable product. Our many years of experience in dealing with inverter systems in the wind industry, combined with a globally proven service structure, guarantee efficient cutting-edge technologies, an attractive profitability of ownership ratio as well as global supply capability of spare parts and service provisions. The Inverters developed and manufactured in Diepholz have proven themselves in various regions and ensure efficient plant performance.

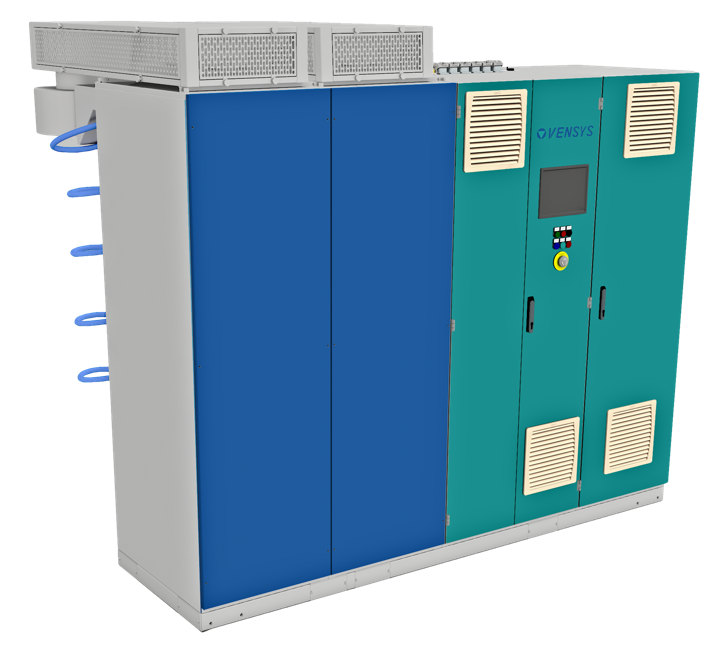

VENSYS VENCON INVERTERS

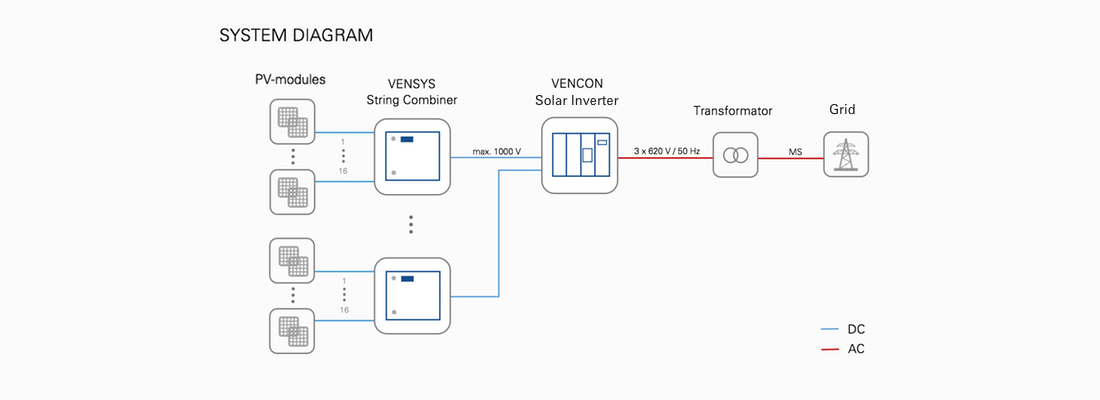

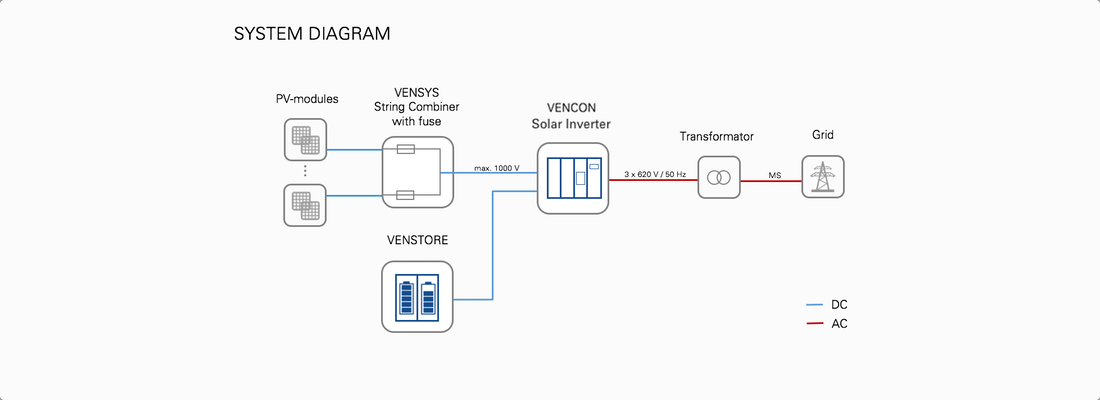

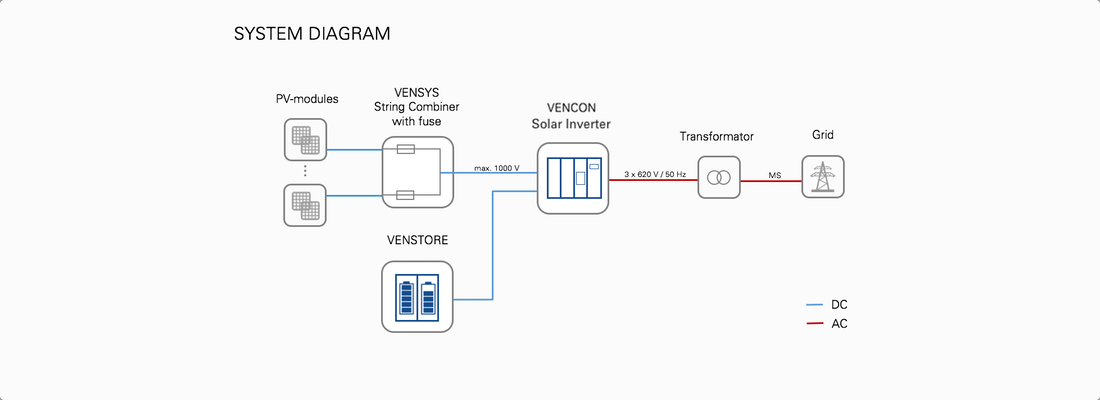

VENCON PV-Inverters increase the overall efficiency and reliability of your solar park. The VENCON Series provides a profitable way to convert the direct current, generated by the solar modules, into valuable and CO2-free alternating current and feed it into the grid.

Years of experience and a proven technology platform have been re-combined to develop the VENCON Series. With its high range from 100 kW to 2000 kW, the VENCON PV-Inverters are designed to be the ideal solution for large scale applications such as solar power plants and industrial buildings.

VENSYS CONVERTERS - HIGHLIGHTS: POWERFUL

- High efficiency rate and optimized MPP tracking

- Proven design with more than 15 GW of installed power

- Best grid compatibility: All grid codes

- Usage of multiple energy sources possible (Solar and VENSTORE battery storage)

- First-class safety standards thanks to protective devices and precise monitoring

- Innovative cooling system with extended temperature range

- Minimized electromagnetic interference due to symmetrically grounded intermediate circuit

- Free of voltage-induced degradation (PID)

- Quality ‘Made in Germany’

Success factors of the VENCON Inverters

MAXIMUM YIELD

The VENCON inverter is characterized by its high efficiency rate ensuring that the generated energy is fed into the grid with minimal loss. Here, the precise and optimal system control and in-house MPP tracking (maximum powerpoint tracking) are unique attributes to the VENCON inverters.

APPLICATION

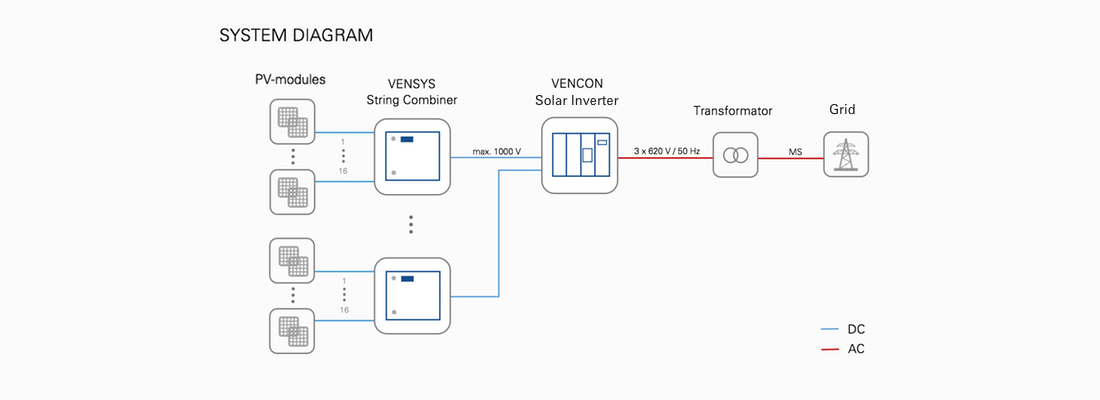

VENSYS STRING COMBINER

The VENSYS String Combiner ensures that all strings in the solar field are collected intelligently and safely and offers ideal monitoring capabilities. They guarantee a harmonious interplay with the VENCON Series resulting in significant reduction in errors and correspondingly an increase in efficiency.

COMPACT AND MODULAR DESIGN

The compact design stands for low system costs, easy maintenance and quick installation. Thanks to the modular system design, VENCON PV-Inverters can be configured and delivered according to customer requirements at short notice. The optimized ‘Plug & Power Container Solution’ is available for outdoor use.

CONFORMITY

The VENCON Series offers extensive compliance with all local network connection standards. These can be adapted to individual country supply requirements.

SERVICE UND SUPPORT

The worldwide VENSYS Service Network supports our customers and partners on a wide range of activities. Starting with preventive Due-Diligence measures through installation and commissioning all the way to spare part supplies and repairs. Options to extend warranties as well as different service packages provide the necessary flexibility.

VENCON INVERTERS - CERTIFICATES:

TECHNICAL DATA

VENCON 1500

VENCON 2000

OVERVIEW

| VENCON 1500 | VENCON 2000 | |

|---|---|---|

| Version | Indoor / Container solution | Indoor / Container solution |

| Inverter type | 1.5 MW Inverter Solar/Storage | 2.0 MW Inverter Solar/Storage |

| Principle | IGBT inverter | IGBT inverter |

| IGBT Type | SKiiP 3-technology | SKiiP 3-technology |

| Supply voltage (AC) | 400 V AC, 3-phases | 400 V AC, 3-phases |

| Total weight | 2.300 kg / 9.500 kg | 2.700 kg / 10.000 kg |

| Dimensions Indoor / Container solution (WxDxH) | 2.600 x 826 x 2.080 mm / 6.058 x 2.438 x 2.591 mm | 2.600 x 826 x 2.080 mm / 6.058 x 2.438 x 2.591 mm |

| Protection class | IP 54 | IP 54 |

| CONNECTIONS AC SECTION | ||

| Rated AC voltage | 620 V, 3-phase-system | 620 V, 3-phase-system |

| Type | Without transformer (IT / TN-grid) | Without transformer (IT / TN-grid) |

| Rated AC current | 1397 A | 1860 A |

| Apparent power | 1500 kVA | 2000 kVA |

| Rated power | 1500 kW | 2000 kW |

| DC-link voltage | ± 575 V | ± 575 V |

| IGBT switching frequency | 2,4 kHz | 2,4 kHz |

| Rated frequency (fr) | 50 Hz | 50 Hz |

| Frequency range | 47,5 – 63 Hz | 47,5 – 63 Hz |

| Adjustable displacement power factor (cos φ) | 0.925 overexcited to 0.925 underexcited | 0.925 overexcited to 0.925 underexcited |

| THD at nominal load | THD ≤ 4,0 % (EN-50160, IEC61000-3-6) | THD ≤ 4,0 % (EN-50160, IEC61000-3-6) |

| Overcurrent protection (lmax) | 1600 A | 2100 A |

| CONNECTIONS DC SECTION | ||

| Number of independent MPP inputs | 1 | 1 |

| Number of DC connections | Max. 18 | Max. 24 |

| Short circuit protection per input | 200 A gPV fuses | 200 A gPV fuses |

| MPP voltage range | 400 – 1000V V | 400 – 1000 V |

| Max. input current | 2028 A (3 x 676 A) | 2028 A (3 x 676 A) |

| Max. open-circuit voltage | 1100 V | 1100 V |

| EFFICIENCY | ||

| Efficiency rate (EUR) | 98,7 %* | 98,6 %* |

| Standby self-consumption | < 200 W | < 200 W |

| CONTROL | ||

| Main control system | WAGO fieldbus-controller | WAGO fieldbus-controller |

| Power interface | WAGO MODBUS | WAGO MODBUS |

| External communication | TCP / IP | TCP / IP |

| COOLING | ||

| Cooling system | VENSYS Water Cooling | VENSYS Water Cooling |

| Cooling principle | Water cooled | Water cooled |

| Working pressure (setpoint) | Approx. 2 bar | Approx. 2 bar |

| Refrigerant | Water - Ethanol mixture | Water - Ethanol mixture |

| ENVIRONMENT | ||

| Operating temperature range | – 20,0 °C … + 45,0 °C (ohne derating) | – 20,0 °C … + 45,0 °C (ohne derating) |

| Storage temperature range | – 30,0 °C … + 60,0 °C | – 30,0 °C … + 60,0 °C |

| Max. relative humidity | 95.00 % (not condensing) | 95.00 % (not condensing) |

| Max. installation height (altitude) | < 1,500 m (above sea level) | < 1,500 m (above sea level) |

| SAFETY AND APPROVAL | ||

| Noise emission | Max. 75 dB | Max. 75 dB |

| DC protection device utzart |

Switch-disconnector | Switch-disconnector |

| Overvoltage protection category | Type 2 | Type 2 |

| Lightning protection class | Optional | Optional |

| Overvoltage protection category (self-supply) | Type 2 | Type 2 |

| Compliance | EN 55011 / EN 55016 / IEC 60068 / IEC 61683 / IEC 61721 | EN 55011 / EN 55016 / IEC 60068 / IEC 61683 / IEC 61721 |

| Certificates | BDEW / TC2007 / FGW TR3 / FGW TR4 | BDEW / TC2007 / FGW TR3 / FGW TR4 |

IMPRESSIONS

VENSYS STRING COMBINER

PV modules must be connected parallel to the central inverter; The powerful and compact String Combiner by VENSYS Electronics GmbH serves this purpose. Whether indoors or outdoors, thanks to their efficient and robust design the boxes are easily installed stand for durability and maximum safety in the PV field.

The innovative and pre-installed monitoring system enables an optimal management of each solar module individually, thus achieving maximum output from your solar park.

THE HIGHLIGHTS: POWERFUL

- Safe and efficient collection of up to 16 strings

- Compact and robust housing for indoor and outdoor applications

- Easy installation thanks to an optimised design and low weight

- Innovative monitoring system

- Excellent safety standard thanks to protective features and optimal monitoring

- Operation at ambient temperatures from -20 °C to 45 °C

Well thought-out down to the tiniest detail

ROBUST AND COMPACT

The robust housing ensures the protection against foreign matter and bad weather conditions with safety class IP55 or optionally IP65, at an operating temperature between -20 °C and +45 °C. In addition, the simple design and low weight allow for quick and easy installation and maintenance.

POWER AND CONNECTION

The VENSYS String Combiner offers 16 string inputs that are connected in pairs and can be operated with up to 150A as well as 1000V. All inputs are equipped with PV fuses (all poles) and are brought together on a load-break switch. The sealing range measures 22 to 36 millimeters, and cable cross-sections between 70 and 2 x 240 mm² are compatible.

CONTROL AND SAFETY

TECHNICAL DATA

IMPRESSIONS

PHOTOVOLTAIC CONVERTER

The All-rounder among the Converters

Specially engineered as a modular central converter, it features high design flexibility for the complete PV system through three MPP trackers and a broad voltage range

Modular: Modular: Expandability in steps of 150 kW means total power can be reached for all sizes.

Versatile Three different strings with an output of 120 kW each can be operated in a broad voltage range, making the most diverse module configurations possible.

Easy to maintain: The modular design, air cooling and the ability to control the system remotely (Web Interface) make sure VENCON requires only a minimum amount of maintenance.

Flexible Thanks to its compact design VENCON is suitable for use in any location.

HYBRID CONVERTER

The All-rounder among the Converters

The central unit for a versatile island grid with a wide range of energy sources.

Modular: Expandability in steps of 150 kW means total power can be reached for all sizes, with several systems being linked via the DC connection.

Versatile Up to six completely different DC sources with up to 120 kW output can be operated in a broad voltage range.

Unbalanced load capability: Due to sufficient intermediate circuit capacity, the converter provides an unbalanced load capability of 100 %.

Backup capability: The integration of diesel generators as well as wind and water power plants is possible without restrictions.

Easy to maintain: The modular design, air cooling and the ability to control the system remotely (Web Interface) make sure VENCON requires only a minimum amount of maintenance.

Flexible Thanks to its compact design VENCON is suitable for use in any location.

THE VENSYS SERVICE - WORLDWIDE, EFFICIENT AND QUICK

VENSYS SERVICE - HIGHLIGHTS:

- comprehensive monitoring and evaluation

- Available around the world

- Highly qualified engineers and technicians

- Efficient maintenance management (diagnostics and upgrades)

- Maintenance and Service On-Site for converter (wind/solar), mean-voltage transformers as well as control gears

- Spare parts available from licensees around the world

WHAT MAKES VENSYS SERVICE SO SPECIAL:

A unique service and support structure sets us apart from our market competitors;

through close cooperation we create clarity about complex issues.

LONG TERM SERVICE AGREEMENT (LTSA):

The LTSA is our customer-friendly “all inclusive” package. With our LTSA, operators can calculate all operating costs of their WEC – conveniently and hassle-free. The technical availability guarantee provides operators with optimal planning security for their projects.

MAINTENANCE SERVICE AGREEMENT (MSA):

The Maintenance Service Agreement MSA is geared to the individual needs or wind farm operators. With our MSA, operators can use their own service structures, provided that they comply with VENSYS requirements. In doing so, operators can rely on the support of VENSYS technicians any time.